By Harriet Wood

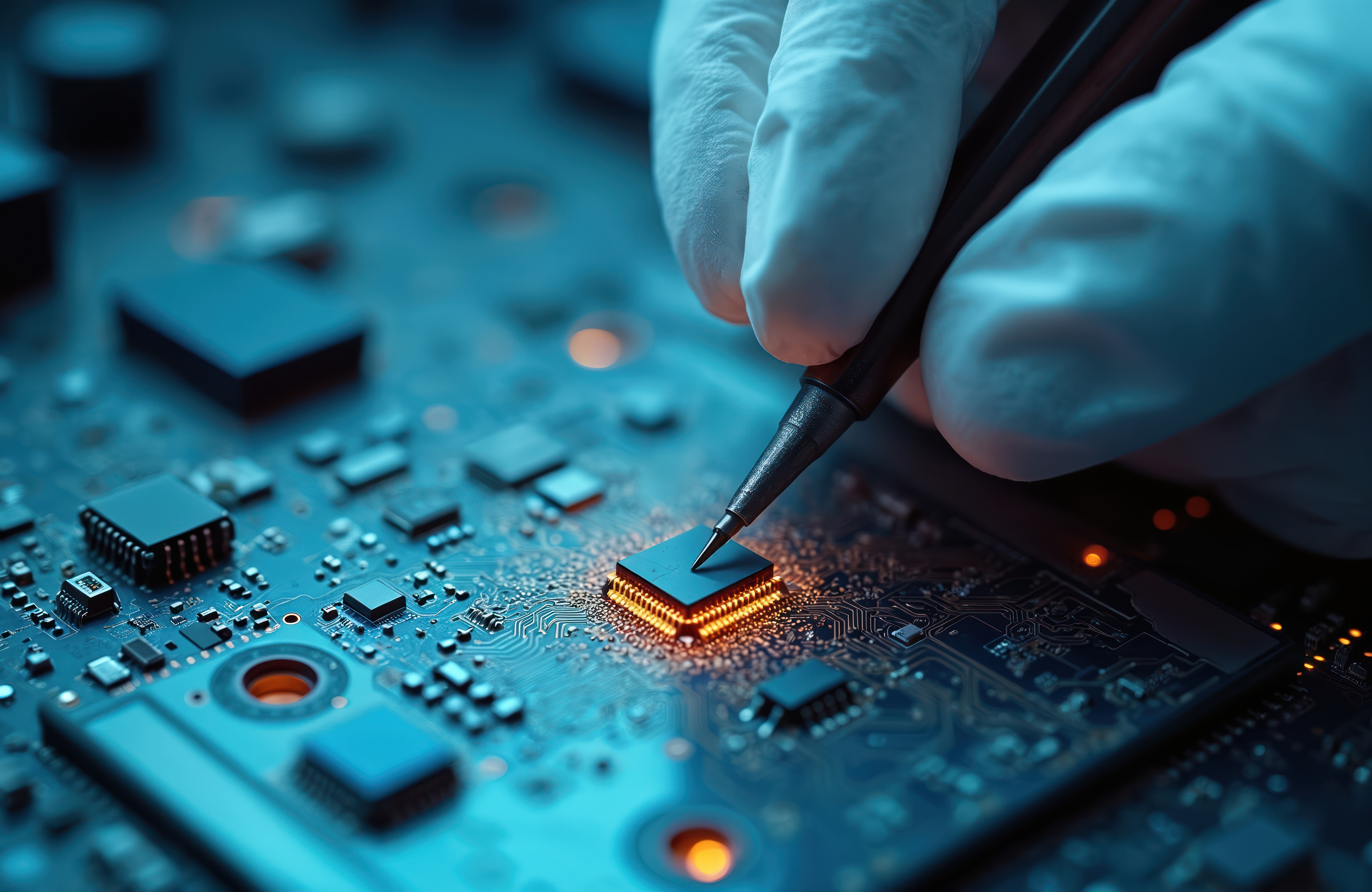

Some of the smallest microchips to ever be manufactured may be in mass production towards the end of 2025, and will likely find their way into the latest phones. However, how exactly do they work, and how much progress has been made?

The ‘Semiconductor device fabrication’ is the name given to a series of technological developments in creating progress nodes within microchip transistors that are as small as they can possibly be. The latest functional microchip with the smallest size gate and metal pitches as the 2-nanometre (or 20 Ångstrom) process chip, manufactured by IBM.

This is an improved version of the previous 3-nanometre chips with a faster speed, efficiency, and is also more compact.

However, the title of these chips is slightly misleading. Unfortunately, the name ‘2-nanometre microchip’ does not refer to the actual size of the microchip or the processing nodes, but is just a marketing label. In fact, the actual ‘2-nanometre microchips’ need at least a 20-nanometre metal pitch and 45-nanometre gate pitch internally. Mass production of these microchips is expected in the latter half of 2025, with larger companies such as Samsung planning to produce them too.

In the future, we can expect the existence and production of a 1-nanometre process microchip generation, projected for roughly 2027. This generation of chip has already been conceptualized as of April 2025 by students at Fudan University in Shanghai, China. Chips of this size will become a necessary change to power the latest AI systems and work at an overall higher performance.

Apple may also invest in using these chips, though the latest iPhone 16 contains the Apple A18 microchip which only has a 3-nanometre process.

Miniaturisation of microchip processing nodes has been in development since 1968 with the 20-micrometre chip generation, and has come very far since then.